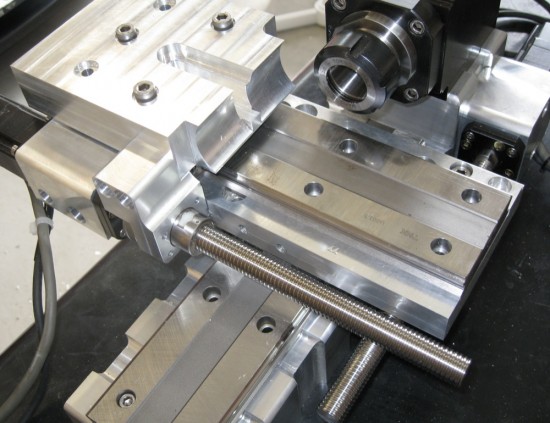

This is a small lathe currently under construction, a basic prototype to test the theory and gain some hands on knowledge. It's work envelope is roughly 2 x 6", it has fine pitch ground ball screws and brushless servos for both the axis and spindle drive.

For it's size, it should be nicely solid, and will hopefully be capable of turning out some nice work. The tooling will be mounted along the front and side of the tool holder block (gang tooled), and there should be room for turning, threading, boring, drill, centre drill and cutoff tools. It'll be a tight fit, but with some optimization I expect it will work well.

The next stage will be live tooling to allow a greater variety of workpieces to be produced.

Once it's all working, I'll tidy up the design and look to building a larger version, with a view to eventually adding a turret also.

UPDATE:

The Lathe is almost ready. The electronics are wired up, the servos are tuned, and there's only a couple of minor details left before we can give it a try. We're waiting on half a flexible coupling for the X axis, and the way covers...

I made a short clip of jogging the Z axis and the spindle running, starts at 1 rpm then up in several steps to 4000 rpm. Nice and smooth, very quiet (the camera microphone makes it sound much louder than it is - you might want your volume down a little):

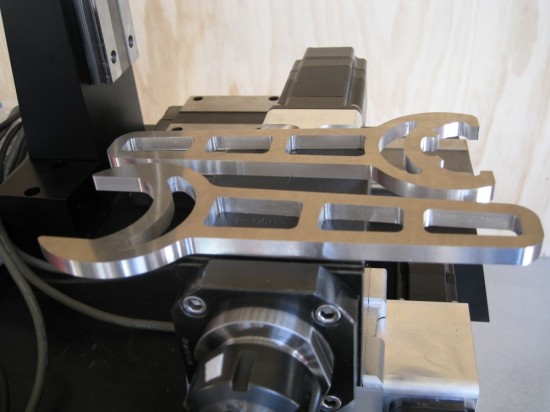

I also needed a set of spanners to close the collet chuck, so I made some on the desktop CNC mill (another loud video):

8 December 2009

Just realised I didn't update this page once the lathe was working. Oops... Here we go, first try in Stainless Steel:

Here's a video turning a scale model of an ISO tool holder:

It needs more tools and decent way covers, but they might have to wait for the next version :)

Comments

Regards,

Jason

Best regards,

Jason

what ball screw are you using, i can't find fine pitch on line... not for a reasonable price at least :)

cheers.

marco

They were NSK, 16 mm diameter, either 2 or 2.5 mm pitch. Yes, they're pretty hard to find new AND reasonably priced...! I used them because the fine pitch was ideal with the tiny servos, and they have very compact ball nuts. 12 mm diameter would have been as good, I did have quite a few that size but they're all gone now too.

I still have one source, but they're getting low on stock too :(

Regards,

Jason

the project i'm working is based on the same structure, with the linear rail as a bed. In my case i can have a BIG roller rail (40mm rail), very rigid but it leaves me with the saddle hanging in the air. Your rails are wider although less rigid.

It'll bee something like 80mm dia. spindle 300mm between centers, assisted manual lathe. Do you think it will be a problem from your experience?

cheers, and merry Xmas

marco